From:

41.30 €

From:

5.97 €

From:

10.20 €

From:

2.60 €

From:

11.20 €

From:

37.10 €

From:

5.13 €

From:

6.01 €

From:

7.71 €

From:

10.30 €

From:

26.60 €

From:

14.50 €

From:

12.60 €

From:

9.29 €

From:

4.99 €

From:

27.50 €Bronze turnbuckles are generally more affordable and offer good corrosion resistance in marine environments. However, AISI 316 stainless steel provides superior corrosion resistance and longer lifespan, making it the ideal choice for boats that frequently sail offshore or in extreme environmental conditions. Stainless steel is also more resistant to tensile and breaking forces compared to bronze.

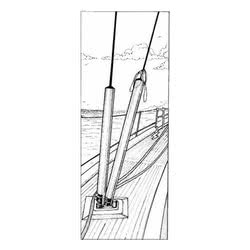

Turnbuckle installation depends on the model type. Generally, you need to connect the turnbuckle to the wire or shroud using a terminal (e.g., a swage terminal or a jaw). Ensure all components are properly sized and compatible with each other. Carefully follow the manufacturer's instructions and, if necessary, consult a professional for safe and correct installation.

To adjust shroud tension, loosen the turnbuckle's locknuts. Rotate the turnbuckle body to lengthen or shorten the wire's length. Use a rigging tension gauge to measure shroud tension and ensure it is uniform on both sides of the boat. Once the desired tension is achieved, tighten the locknuts to prevent the turnbuckle from loosening.

Turnbuckle covers are fabric or plastic protectors used to cover turnbuckles. They primarily serve to protect turnbuckles from corrosion, UV rays, and the elements, extending their lifespan. Additionally, turnbuckle covers can prevent injuries by preventing people from scratching themselves or getting caught on the turnbuckles.

Signs of wear that indicate the need to replace a turnbuckle include: obvious corrosion, cracks or deformations, difficulty rotating the turnbuckle body, damaged or loose threads, and signs of wear on the terminals. If you notice any of these signs, it is important to replace the turnbuckle as soon as possible to ensure the safety of your boat.

Bronze turnbuckles are generally more affordable and offer good corrosion resistance in marine environments. However, AISI 316 stainless steel provides superior corrosion resistance and longer lifespan, making it the ideal choice for boats that frequently sail offshore or in extreme environmental conditions. Stainless steel is also more resistant to tensile and breaking forces compared to bronze.

Turnbuckle installation depends on the model type. Generally, you need to connect the turnbuckle to the wire or shroud using a terminal (e.g., a swage terminal or a jaw). Ensure all components are properly sized and compatible with each other. Carefully follow the manufacturer's instructions and, if necessary, consult a professional for safe and correct installation.

To adjust shroud tension, loosen the turnbuckle's locknuts. Rotate the turnbuckle body to lengthen or shorten the wire's length. Use a rigging tension gauge to measure shroud tension and ensure it is uniform on both sides of the boat. Once the desired tension is achieved, tighten the locknuts to prevent the turnbuckle from loosening.

Turnbuckle covers are fabric or plastic protectors used to cover turnbuckles. They primarily serve to protect turnbuckles from corrosion, UV rays, and the elements, extending their lifespan. Additionally, turnbuckle covers can prevent injuries by preventing people from scratching themselves or getting caught on the turnbuckles.

Signs of wear that indicate the need to replace a turnbuckle include: obvious corrosion, cracks or deformations, difficulty rotating the turnbuckle body, damaged or loose threads, and signs of wear on the terminals. If you notice any of these signs, it is important to replace the turnbuckle as soon as possible to ensure the safety of your boat.

90% of the orders are shipped within 24H. Have a look at the availability and shipment time in the product page

We work on boating since 1982. You will find experienced and polite staff

You can choose between Paypal, Credit Card, Postepay and Transfer

We only use packaging from recycled material within our own store